Making room for new arrivals

Shop by category

Daycare essentials

Getting kids to daycare on time and with everything they need can be a everyday hassle. But not to worry - we got you covered. Here's all the essential gear you'll need for a great start.

Ready for outdoor action

Our hybrid jackets and pants keep up with active kids! Waterproof where needed, flexible and dirt-repellent everywhere else—perfect for play and everyday wear, all year round.

Back-to-school made easy

From comfort in the classroom to playground fun – Reima brings you the best-performing back-to-school gear all in one place. Combining quality, functionality, and style ensures that our clothing will last through the school year and even to the next kid.

Enjoy the puddles like a duck

Let your kid experience total barefoot bliss in the rain - with dry feet! The zero heel Reima barefoot rain boots Ankka are wide enough for tiny toes to grow straight. The outsole is grippy, yet flexible for connecting with Mother Earth.

Well-being starts from the feet

Active kids expand their world with every step. Reima shoes let kids find their fun outdoors - no matter the weather.

Set them free in new Barefoot shoes

From singletrack to sidewalks, our Barefoot shoes let kids conquer any adventure with a gait that's natural and unrestricted. Packed with top tech, offering full freedom for growing feet, they're designed for grip and protection throughout every outdoor adventure.

Drenched in fun

Make rainy days just as fun! Our complete waterproof collection ensures kids are dressed head to toe in waterproof coats, boots, and everything they need. Let them splash and explore, no matter how hard it pours.

Unbeatable everyday comfort

Discover our Everyday Collection, featuring new colors and fresh styles for spring! From cozy sweaters and sweatpants to breathable shorts and t-shirts, each piece is crafted with a relaxed fit and premium quality. Perfect for everyday wear, these essentials ensure your kids look and feel their best.

Reima x Moomin

The door is always open—to adventure

In honor of the Moomins' 80th anniversary, we’re excited to bring you another Reima x Moomin collection featuring Tove Jansson’s iconic art. Made for little explorers, inspired by Finnish courage and curiosity.

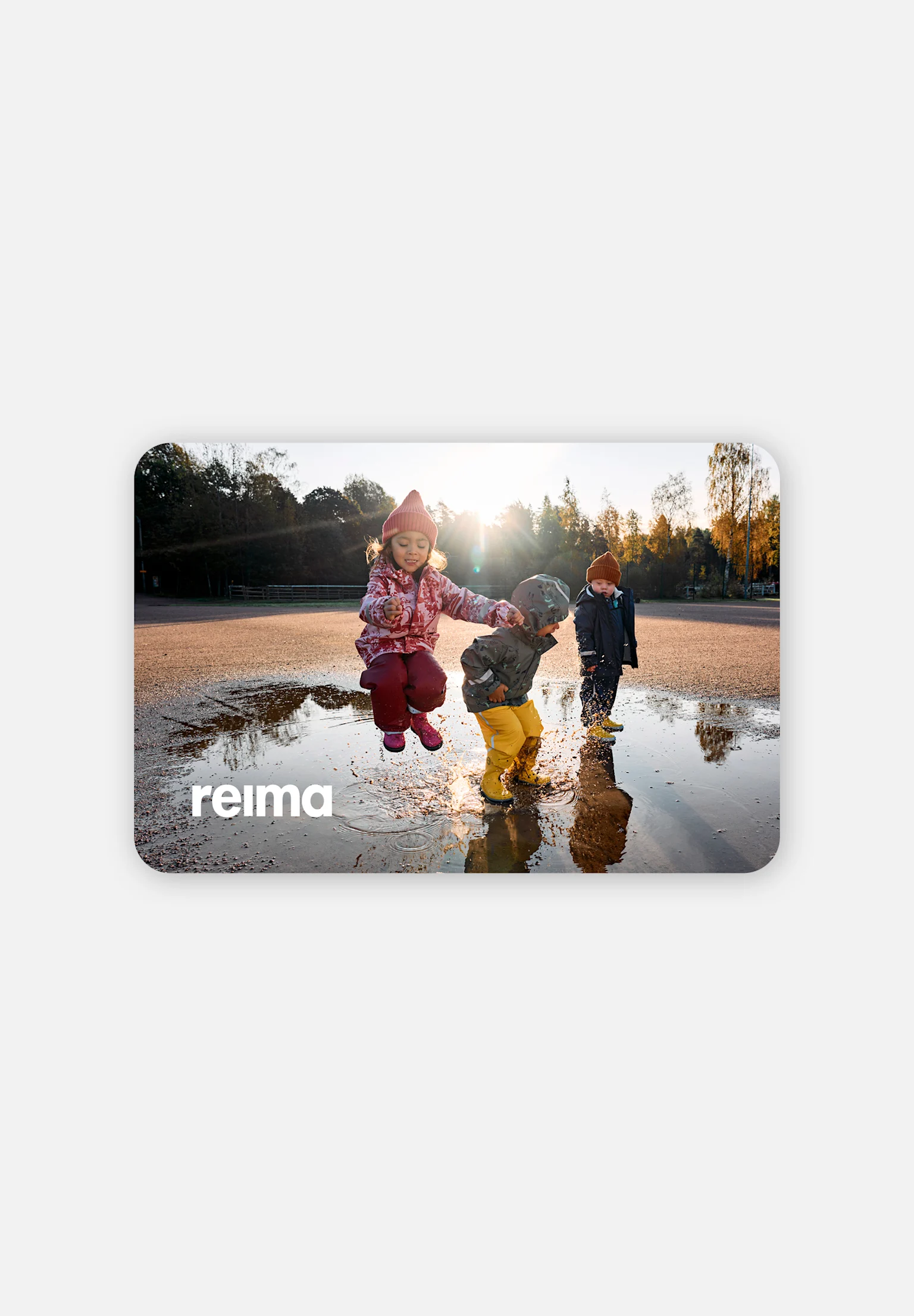

The perfect gift, every time

Not sure what to choose? Reima gift card is the thoughtful choice that never disappoints. Our digital gift card is valid for a whole year and can be used online or in-store, offering the freedom to choose exactly what’s needed. Choose your desired sum for the gift card, and it’s delivered straight to your email—fast and hassle-free.

This is what sustainability looks like

A child’s joy is our most important responsibility as adults. At Reima, we provide the gear so you can focus on what’s essential; nurturing curiosity, inspiring adventure, and creating joy. Your kid can enjoy outdoors in gear that's protective, non-toxic, and made from superior materials.

READ MOREAbout us

We believe that small ideas can have a big impact. This is why, for over 80 years, we've had our hearts set on one thing: to create clothes and services that let kids live curiously, whatever the weather.

READ MORE

Kids clothing for active kids

Reima is the leading premium performance wear brand for active children. We provide a good quality, year-around, tip-to-toe wardrobe for children, ages 0 to 12. We want them to discover the joy of movement, which will stick with them for the rest of life. Reima has been here for every day, every weather, every experience, wherever adventure awaits, since 1944.

We have the best selection within outerwear, like jackets for both summer and winter and trousers as well. Designed to handle any winter weather, our award-winning snowsuits are renowned for their exceptional warmth and waterproofing, making them a staple choice for all winter adventures. All our outerwear is perfect for demanding and changing weather in all seasons. For the sunny days, we have a great UV-protective swimwear collection, with a sun protective factor 50+. For the rainy days, you find colourful rainwear, made of safe flexible materials. Functional mid layers and innerwear is what makes the kids able to play for a long time.

We have a great selection of kids’ shoes, waterproof, functional and machine-washable. Everything your kid’s needs, when they go out and have fun whatever the weather.

As Reima is a company that focuses 100% on kids, we also look at sustainability through the same lens. We always ensure non-toxic clothing, footwear and accessories that allow kids to move and explore the world around them.

Welcome.